Hardware: Traditional hardware products, also known as "hardware". Refers to gold, silver, copper, iron, tin five metals. After manual processing can be made into knives, swords and other art or metal devices. Modern society's hardware is more extensive, such as hardware tools, hardware parts, daily hardware, building hardware and security supplies. Most hardware products are not consumer goods.

Strictly in accordance with ISO9001, ISO14001 system production, PQE, DQE to ensure quality

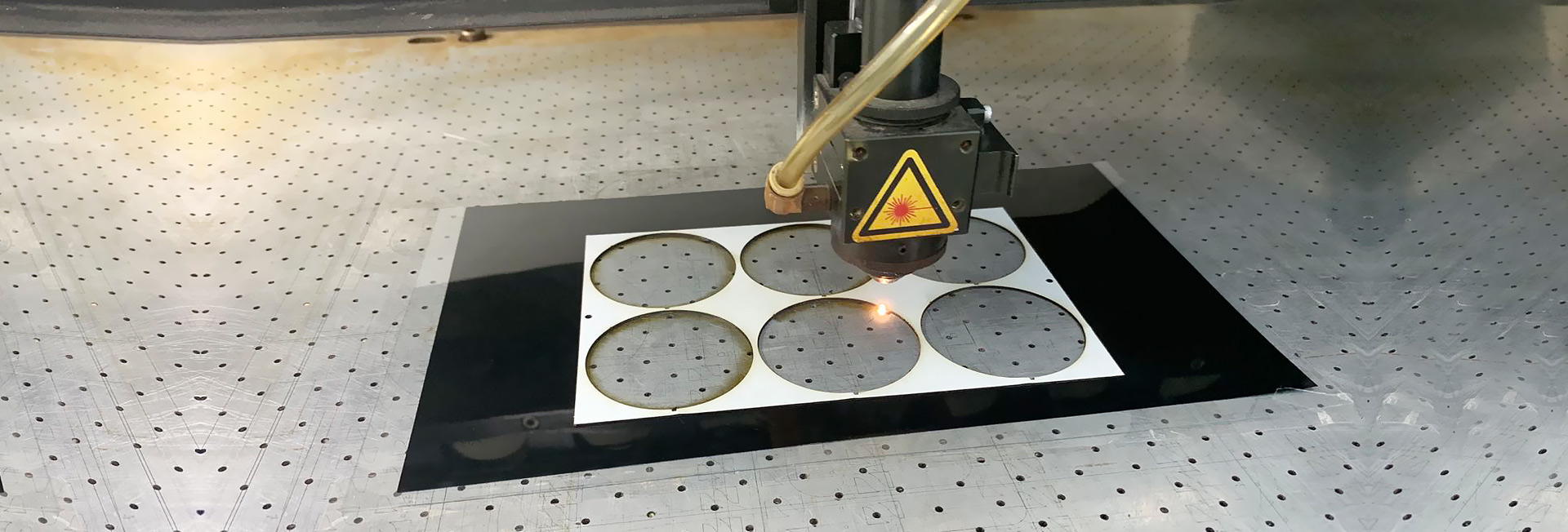

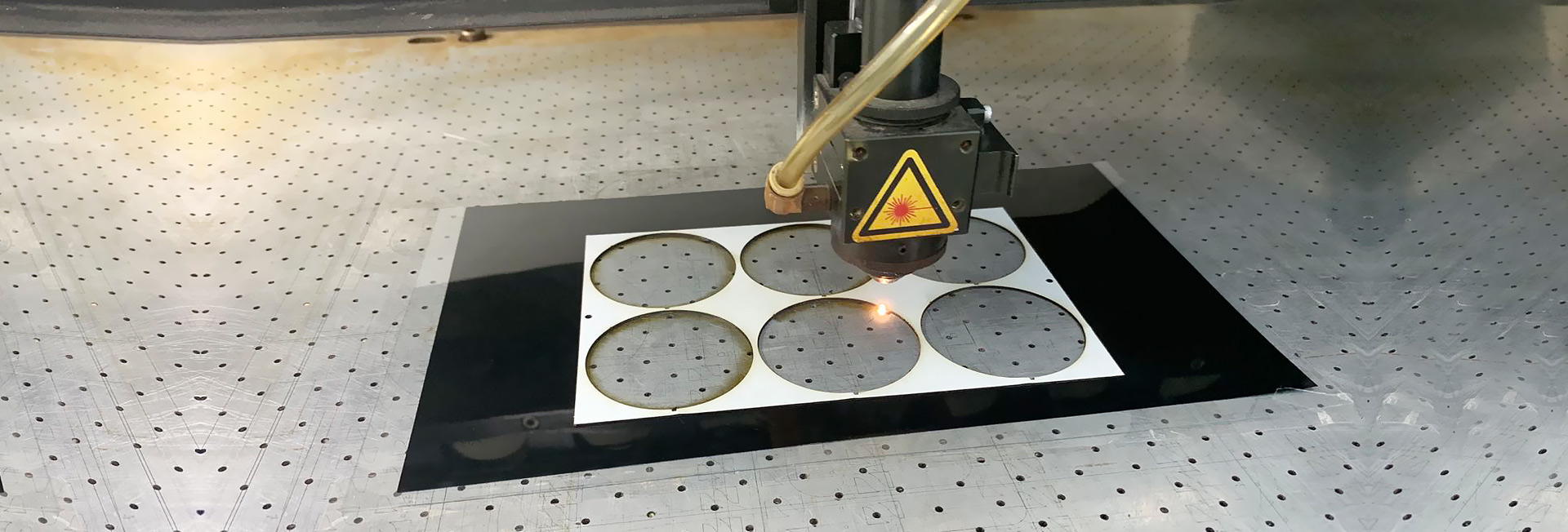

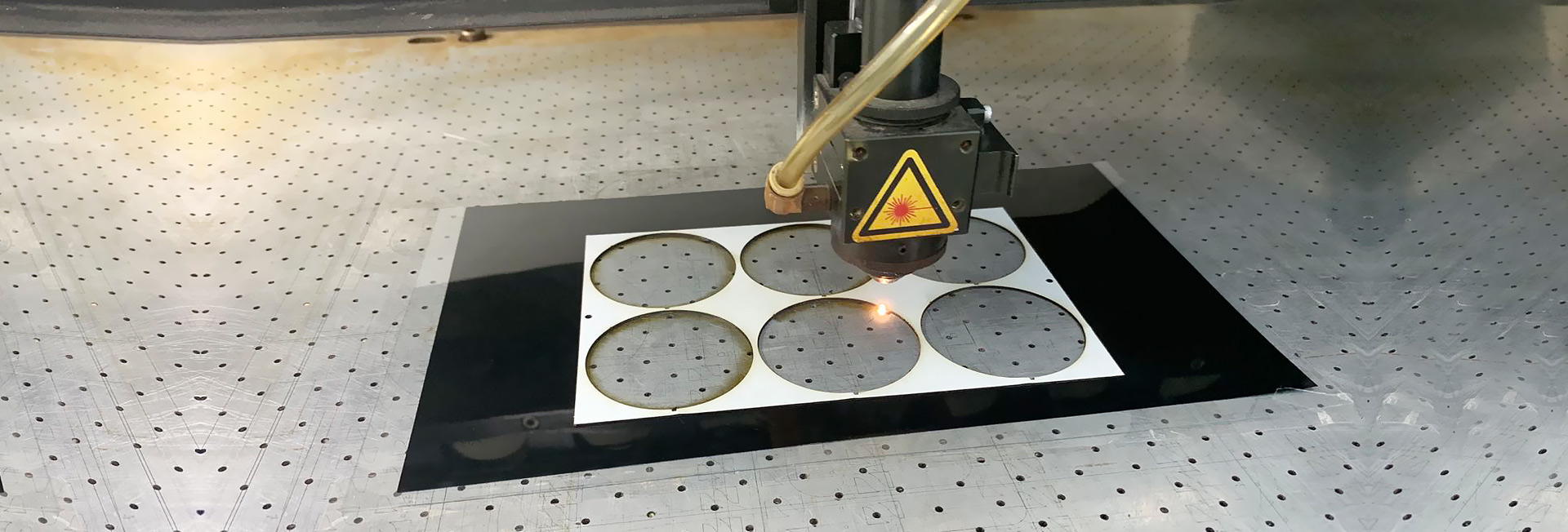

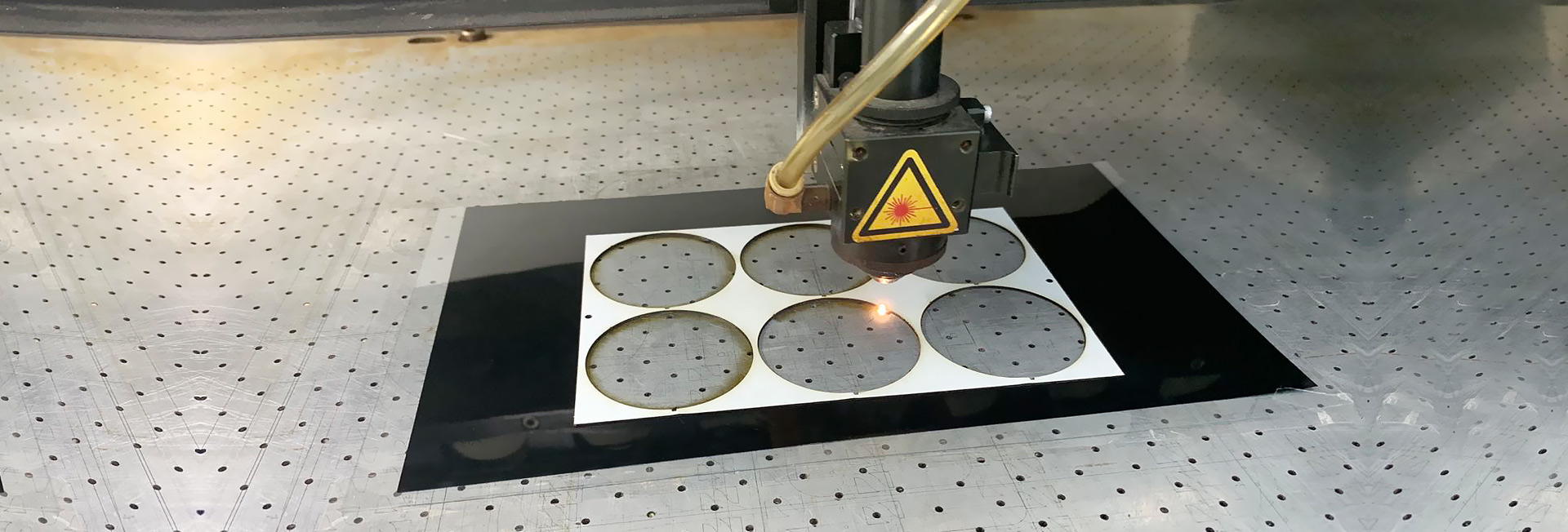

Use five tools APQP, FMEA,PPAP, SPC and MSA to control production quality

2.5 Dimensional measuring instrument, constant temperature and humidity machine, salt spray testing machine and other testing equipment

Perfect quality system -IQC testing, IPQC testing, FQC testing, OQC testing, to ensure that products qualified

Sample department according to customer renderings free sample, 3 days fast sample, 31 years of Ming board, hardware, LOGO processing Production experience, several stamping, machining, printing production line, assembly line, etc., strong production capacity

consultation

consultation

Sample department according to customer renderings free sample, 3 days fast sample, 31 years of Ming board, hardware, LOGO processing Production experience, several stamping, machining, printing production line, assembly line, etc., strong production capacity

consultation

consultation

Sample department according to customer renderings free sample, 3 days fast sample, 31 years of Ming board, hardware, LOGO processing Production experience, several stamping, machining, printing production line, assembly line, etc., strong production capacity

consultation

consultation

Sample department according to customer renderings free sample, 3 days fast sample, 31 years of Ming board, hardware, LOGO processing Production experience, several stamping, machining, printing production line, assembly line, etc., strong production capacity

consultation

consultation

Three, four wing axis type manual, automatic revolving door

Three wing center shaft manual revolving door

Three wing manual and automatic revolving door with display case

Understand customer needs in time and discuss solutions

Deepen the design drawing and give the customer feasibility advice from the production point of view

Quick response and timely offer

3 days for sample production, 10 days for mold production

Reliability test, full scale measurement, attached inspection report to customer

The customer signs and confirms the process